Vancouver, British Columbia, February 1, 2024 – Québec Nickel Corp. (CSE: QNI; FSE: 7lB; OTCQB: QNICF) (“QNI” or the “Company”) announces results from the metallurgical test work program completed on Ni-Cu-PGE-rich drill core from the Fortin Sill Zone at its 100% owned Ducros Project near Lebel-sur-Quévillon, Québec. The objective of the scoping-level metallurgical program is to evaluate the amenability of the Fortin Sill Zone to produce saleable Critical Metals-bearing mineral concentrate(s).

Highlights:

- Copper concentrate grades of 30% Cu with greater than 90% recovery achieved;

- Nickel concentrate grades of 5% Ni with recoveries averaging 72% realized;

- Ball mill hardness testing indicates the sulphide-rich rocks are classified as “moderately soft”;

- Environmental characterization of the combined tails did not identify any notable leachable metals.

David Patterson, QNI’s CEO and Chairman, remarks “I’m happy to see these strong test results confirm what we were thinking as soon as we saw the core come out of the ground at the Fortin Sill Zone in early 2022. The mineral assemblages and grades found at Fortin are not only quite unique for the Abitibi, but they also look like they could potentially be processed using conventional metallurgical processes. In a very short amount of time, we’ve completed several different technical studies of the host rocks and nickel-copper-PGE mineralization found at Fortin, and all signs suggest we’re onto to something unique and important here.”

Background

The metallurgical study was initiated in 2023 to follow-up on significant drilling results returned from the Fortin Sill Zone including 31.00 metres of 0.37% Ni, 0.40% Cu, 176 ppm Co and 0.55 g/t Pt-Pd-Au in hole QDG-22-09 (see May 16, 2022 News Release), 43.39 metres of 0.24% Ni, 0.25% Cu, 146 ppm Co and 0.35 g/t Pt-Pd-Au in hole QDG-22-28 (see August 30, 2022 News Release) and 11.80 metres of 1.44% Ni, 1,49% Cu, 461 ppm Co and 2.79 g/t Pt-Pd-Au in hole QDG-22-29 (see August 30, 2022 News Release).

During the first half of 2023, the Company completed several dedicated HQ-diameter drill holes at the Fortin Sill Zone that supplied fresh material for the test work program. The metallurgical holes were designed to twin previously completed holes and targeted three styles and grades of Ni-Cu-PGE mineralization including:

- Low grade disseminated and blebby sulphide mineralization with a target average grade of

0.30% nickel + copper; - Moderate grade blebby to heavily disseminated mineralization with a target average grade

of 0.75% nickel + copper; - High-grade net texture to semi-massive mineralization with a target grade of greater than

1.50% nickel + copper.

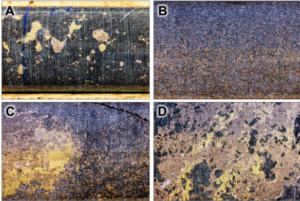

From the metallurgical drilling, three 50-kilogram samples of Ni-Cu-PGE mineralized drill core, each representing one of the styles and target grades of mineralization, were collected and delivered to SGS Canada’s Québec City laboratory for the study. Examples of some of the sampled drill core that was used for this test work program are presented in Figure 1.

Summary of Metallurgical Study Results

Upon preparing a master composite sample from the three variability samples, the four samples were subjected to a metallurgical test program which included amongst other protocols, comminution, floatation and environmental test work. The Bond ball mill grindability test (i.e. comminution), which is used to estimate net power requirements for a potential mill grinding circuit, was performed on the master composite sample. Results from this test show the Fortin Sill Zone rocks are “moderately soft”.

The results from the floatation test work program demonstrate that the mineralized rocks at the Fortin Sill Zone are amenable to producing two distinct mineral concentrates, namely a high-grade

copper + gold + palladium concentrate and a moderate grade nickel + cobalt + platinum concentrate. Copper grades ranging from 28.0 to 29.3% Cu at recoveries ranging from 89.2% to 92.9% were achieved from the four samples. The nickel concentrate grades were relatively low at about 5% Ni for the four samples tested. Nickel recoveries improved significantly from the batch tests and ranged from a low of 48.2% in the low-grade sample to 77.5% in the high-grade sample. A subsample of the combined tailings from the four locked cycle tests was submitted for basic environmental characterization including leachable metals and acid base accounting (ABA). Environmental characterization of the combined tails did not identify any notable leachable metals but found the sample to be possibly acid generating. More detailed information discussing the results of this study can be found appended to the end of this New Release.

Qualified Person

Gary DeSchutter, M.Sc., P.Geo., a Qualified Person (“QP”) as defined under National Instrument 43-101 (“NI 43-101”), has reviewed, and approved the scientific and technical content of this news

release.

About Québec Nickel Corp.

Québec Nickel Corp. is a mineral exploration company focused on acquiring, exploring, and developing critical metals (Ni-Cu-Co-PGE) projects in Québec, Canada. The Company has a 100%

interest in the Ducros Property, consisting of 282 contiguous mining claims covering 15,293 hectares within the eastern portion of the Abitibi Greenstone Belt in Québec, Canada. Additional information about Québec Nickel Corp. is available at www.quebecnickel.com.

The CSE has neither approved nor disapproved the contents of this news release. Neither the CSE nor its Market Regulator (as that term is defined in the policies of the CSE) accepts responsibility for the adequacy or accuracy of this release.

On behalf of the Board of Directors

David Patterson

Chief Executive Officer and Director

1 (855) 764-2535 (QNICKEL)

info@quebecnickel.com

CAUTIONARY AND FORWARD-LOOKING STATEMENTS

This news release includes certain statements that may be deemed “forward-looking statements”. All statements in this news release, other than statements of historical facts that address events or developments that the Company expects to occur, are forward-looking statements. Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the words “expects,” “plans,” “anticipates,” “believes,” “intends,” “estimates,” “projects,” “potential” and similar expressions, or that events or conditions “will,” “would,” “may,” “could” or “should” occur. Although the Company believes the expectations expressed in such forward-looking statements are based on reasonable assumptions, such statements are not guarantees of future performance, and actual results may differ materially from those in the forward-looking statements. Factors that could cause the results to differ materially from those in forward looking statements include market prices, continued availability of capital and financing, and general economic, market, or business conditions. Investors are cautioned that such statements are not guarantees of future performance and that actual results or developments may differ materially from those projected in the forward looking statements. Forward-looking statements are based on the beliefs, estimates, and opinions of the Company’s management on the date the statements are made. Except as required by applicable securities laws,

the Company undertakes no obligation to update these forward-looking statements if management’s beliefs, estimates, opinions, or other factors should change.

Additional Details of the Fortin Sill Zone Metallurgical Program Results

Sample Preparation

Upon receipt at SGS’ laboratory, each of the three 50-kilogram samples of drill core was first stage crushed to 3.3 millimeters (6 mesh), from which 20 kilograms was taken from each sample to create a master composite sample. A 10-kilogram split of the master composite sample was used for Bond Work Index (BWI) testing. The remainder of the four samples (low-grade, moderate-grade, high grade, and composite) were crushed further and split into multiple sub samples that were used forall subsequent test work.

Head Characterization

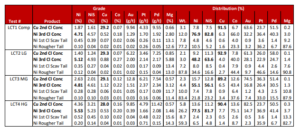

For each sample, a single test charge was randomly selected from which a ~150 g subsample was riffled, pulverized, and submitted for chemical characterization for the metals of interest. The head grade for each of the four samples is presented in Table 1.

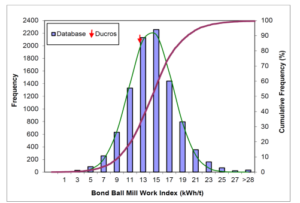

Ball Mill Grindability Test

Bond Work Index (BWI) testing was completed on the 10-kg split of the Fortin Sill Zone composite sample at a closing size of 150 µm (100 mesh). The results were compared to SGS’ internal database, which comprises over 9,000 BWI data points (Figure 2), and at a BWI of 12.5 kWh/t, the Fortin Sill Zone mineralized rocks can be categorized as being “moderately soft”.

Rougher Tests

Four rougher tests were first completed on the composite sample to define the optimal floating conditions, then the best conditions were applied to the low, moderate and high-grade samples. The

variables evaluated include collector type, gangue mineral depressant dosage and addition location in the circuit, as well as addition of copper sulphate as nickel activator.

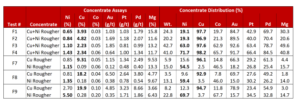

Initial tests with two different sulphide collectors (xanthate and dithiophosphate) with the addition of a gangue mineral depressant (Depramin C) at each of the five rougher stages showed no significant difference in nickel and copper recoveries to the combined rougher concentrate (tests #F1 & F2). An increase in a sulphide collector dosage from 25 g/t to 70 g/t, a single 500 g/t addition of the gangue mineral depressant in the primary grind, along with an addition of a copper sulphate as an activator in test F3, resulted in a dramatic improvement in nickel recoveries from sub 20% to over 60% (Table 2). Substantial boosts to recoveries of cobalt and palladium are also noted in test F3. Test F4 included a selective copper collector (dithiocarbamate) at the copper floatation stage and additional sulphide collector (dithiophosphate) in the nickel circuit further increased nickel recoveries from 63% to 72%.

Table 2. Rougher flotation results for the Fortin Sill Zone mineralized samples. Tests #1-4 were performed on the Fortin Sill Zone composite sample to determine the optimal conditions. Tests #7-9 were completed on the low, moderate and high-grade samples using the optimal conditions.

Cleaner Tests

A total of nine cleaner tests were completed, three on the composite sample and two each on the low, moderate and high-grade samplesto determine if nickel and copper grades and recoveries could be improved. Different combinations and amounts ofsulphide collectors, gangue mineral depressant, and varying regrinding times were evaluated and in general, there was no significant impact on nickel recoveries by increasing retention time.

Locked Cycle Tests

Based on the results of the rougher and cleaner tests, four different locked cycle tests were completed on the composite and the three grade variability samples as per Figure 3. For each of the low, moderate and high-grade samples,separate nickel and copper concentrates were produced. The locked cycle tests gave excellent copper performance, achieving copper grades ranging from 28.0% to 29.3 % Cu at recoveries ranging from 89.2% to 92.9%, which are in-line with the results from the composite sample (Table 3). Nickel concentrate grades average 5% between the four samples and recoveries range between 48.2% in the low-grade sample to 77.5% in the high-grade sample. Cobalt and platinum primarily followed and behaved like the nickel, while gold and palladium mostly followed and behaved like copper. Gold and palladium contents for the copper-rich concentrates range from 6.22 g/t Au (low grade sample) to 9.85 g/t Au (high grade sample) and 7.25 g/t Pd (low grade sample) to 11.42 g/t Pd (high grade sample). The cobalt and platinum contents of the concentrates vary between 0.07% Co (low grade sample) and 0.16% Co (high grade sample) and 3.46 g/t Pt (low grade sample) and 6.21 g/t Pt (moderate grade sample) all at low to moderate recoveries. A comparison of sulphide nickel (NiS) and total nickel (Ni) assays suggests that losses due to nonsulphide nickel minerals are minimal.

Environmental Testing

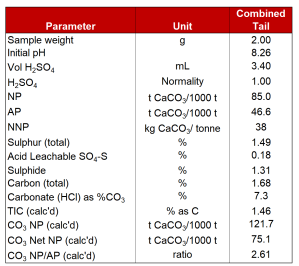

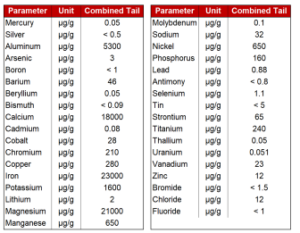

A subsample of the combined tailings from the four locked cycle tests was submitted for basic environmental characterization including leachable metals and acid base accounting (ABA). The solid fraction of the sample was partially digested in accordance with the moderately aggressive Quebec Ministry of the Environment Protocol M.A. 200 – Met 1.2 digest. Environmental characterization of the combined tails did not identify any notable leachable metals (Table 4).

Acid base accounting (ABA) testing was completed using the Quebec Acisol 1.0 method to assist in determining the propensity of the solids to generate acidic conditions. The ABA test provides quantification of the total sulphur, sulphide sulphur, and sulphate concentrations present and the potential acid generation (AP) related to the oxidation of the sulphur concentration. The test method determines the neutralization potential (NP) of the sample by initiating a reaction with excess acid, then back titrating to pH 7.0 with NaOH. Carbonate concentrations will also be analyzed, and Carbonate NP values will be determined. The balance between the AP and NP assists in defining the potential of the sample to generate acid drainage.

Results of the ABA test on the combined flotation tail are summarized in Table 5. With a NP/AP ratio of 2.61, the Combined Tail sample is possibly acid generating and results should be verified via mineralogical characterization.